Since ancient times, man has made use of the impact of water, water wheel, water mill, and other hydraulic machinery. If water is ejected from a high-pressure water gun, the effect is even more significant. In the former Soviet Union, it was used in the coal mining industry, called hydraulic coal mining.

The high-speed water jet is blocked by the coal seam, and the velocity drops suddenly, which will produce enough impact force in an instant to make the coal seam brittle fracture and complete the coal mining operation. Inspired by this, scientists in the former Soviet Union developed high-pressure water jet cutting technology, which was patented and commercialized by an American company.

Ordinary water is pressurized to 4,000 BAR 60,000 PSI through an ultra high-pressure pressurizer, and then through a tiny nozzle with a diameter of 0.004 inches to 0.016 inches, producing a water rocket that travels at about 915 meters per second, nearly three times the speed of sound, this water Arrow can be used for various surface treatment and cutting of non-metallic materials such as paper, diapers, glass, fiber, sponge, etc…

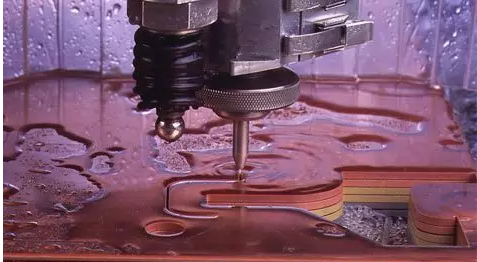

For cutting metal and hard materials such as stone, glass, ceramic, tile, and so on, we have developed a patent and a perfect design, that is, mixing sand with water arrows to enhance its cutting ability, this high-speed sanding water knife can cut almost any material.

To do this, there is a high demand for water, pipes, and vents. For example, a boiler, a water knife, is fired from a powerful tool after the water is pressurized. The pipe must have extremely high pressure to cut the hard cutting material, so the tube must be able to withstand extremely high demand, the pressure is much greater than 700 MPA because the sheet metal itself can withstand 700 MPA of pressure.

Secondly, the water knife with no impurities in the water is wrong. Since the water pressure is much higher than 700 MPA, pure water will wear down and leak through pipes and other sealing equipment, no matter how well sealed. In order to solve this problem, 5% soluble emulsified oil should be added into the water for the water jet to improve the sealing effect. For the high-pressure pump, but also to add some fuel to enhance its sealing performance.

As mentioned above, the nozzle of the water knife is made of hard alloy, Sapphire and other materials, the nozzle diameter is only 0.05 mm, and the bore wall is smooth and smooth, can withstand 1700 MPA pressure, so the jets of high-pressure water can cut through the material like a knife. Some water is also added with long-chain polymers, such as polyethylene oxide, to increase the “viscosity” of the water so that the spray of water like a “thin line. ”

It has high machining precision; cutting width is only 0.1-0.8 mm, can process the parts with complex surfaces. The cut of the processed parts is smooth and neat, with no need to trim. Especially for the processing of natural thermal deformation materials, “water knife” has more unique advantages. The abrasive and wastewater mixed into the water jet can be recycled, the equipment is relatively simple, and the processing cost is low. The vibration and noise are minimal, the chip quantity is only 15% as high as 20% of that of machining, and the chip flows away with the water without flying to the operator.

“water knife,” precisely because it is not a knife, just opened up a wide range of uses. The cutting of composite material is a difficult problem in machining. If the traditional processing method is used, delamination and tearing will occur, and “water knife” is the ideal tool to solve this problem. The “water knife” is superior to mechanical and chemical methods in removing ceramic coatings from components. “water knife” can be used for punching, crushing materials. It is also convenient to clean the fouling on the surface of the ship, propeller, and chemical pipe with a water knife.

Water knives can also be used in surgery. [ the University of Tokyo School of Medicine used 0.7 MPA “water knife” in rabbits; it shows that it can be used for liver, kidney, and other organs surgery, will not damage the surrounding tissue, and not easy to cause infection. )

Leave A Comment