Overview of this article

- Choose a general-purpose guide

- The influence of cutting force on internal circle turning

- The relation between the central deflection angle and the cutting force

- Applications in four main areas

- Guide for selection of internal turning tools

- Selection of Blade Angle

- Relationship between chip area and tip radius

1.Choose a general-purpose guide

In the internal turning and tedious process, the choice of cutting tools is significantly limited by the hole diameter and length of the part.

- Choose the largest possible boring bar diameter and the smallest potential overhang.

- Chip removal is the key factor of successful boring.

- The clamping method has a decisive influence on performance and results.

FACTORS TO CONSIDER:

- Tool and blade groove types: Main deflection angle, blade shape, negative rake / positive rake, blade groove type, tip radius.

- CHIP REMOVAL: Chip Size, cutting control, technology.

- Tool requirements: reduced length, increased diameter, optimized shape, different tool materials, clamping system.

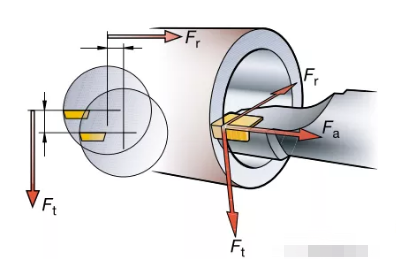

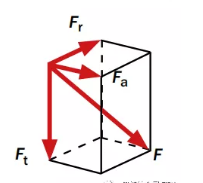

2.The influence of cutting force on internal circle turning.

Radial and tangential cutting forces deflect the boring bar.

TANGENTIAL CUTTING FORCE FT:

- Force the tool down, away from the centerline.

- Resulting in a reduction in the posterior horn.

RADIAL CUTTING FORCE FR:

- Change cutting depth and chip thickness.

- Dimensional tolerance.

FEED FORCE FA: Along the tool feed direction

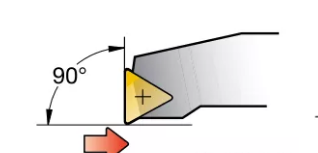

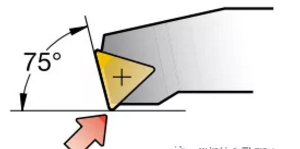

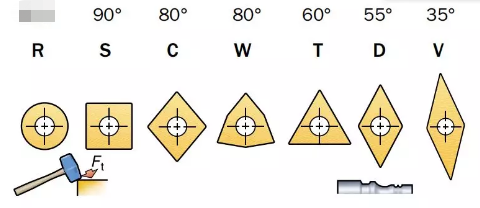

3.The relation between the central deflection angle and the cutting force

- Select the central deflection angle close to 90°.

- If Fr is possible, do not fall below 75°. Otherwise, it will significantly increase the radial cutting force Fr.

- Less radial cutting force, less deflection.

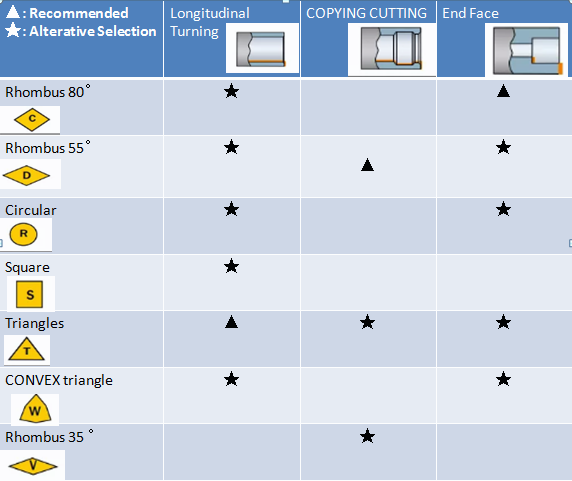

4.Applications in four main areas

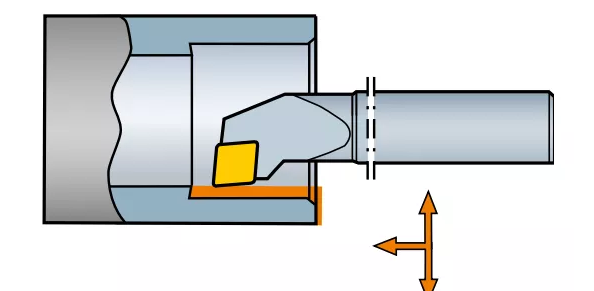

One

Longitudinal turning / turning face

The most common internal turning process

- Commonly used Rhombic c-80° blades.

- Boring bars with main deflections of 95° and 93° commonly used.

- Also widely used are type D 55°, type W 80°, and type T 60° blades.

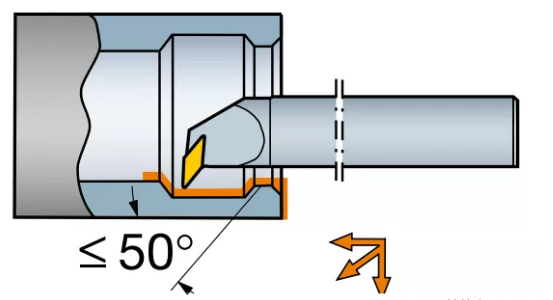

Two

Copying cutting

Diversity and accessibility are the determining factors

- The active principle deflection angle kr should consider.

- The central deflection angle of the boring bar is 93°, which allows 22 °- 27° internal copying angle.

- Commonly used blade shapes are d-55°, v-35°, and t-60°.

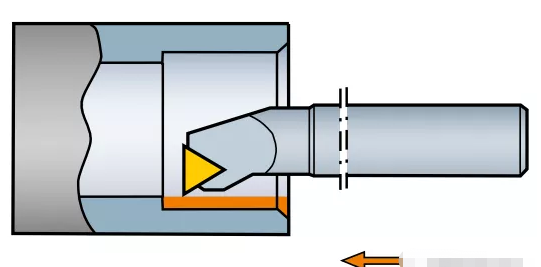

Three-longitudinal turning

Carry out a tedious process to ream the existing hole

- The central deflection angle approaching 90° recommended.

- Use as little overhang as possible.

- Commonly used blade shapes are c type 80°, s type 90, and t type 60°.

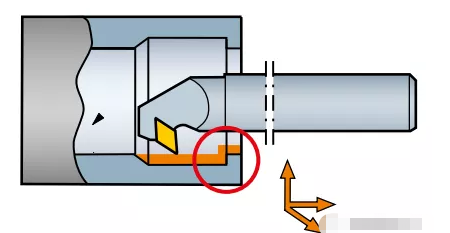

Four

Back Boring

The back boring is a tedious process using a reverse feed

- It is used for turning shoulders smaller than 90°.

- Boring Bar with 93° central deflection angle and D type 55° blade are commonly used.

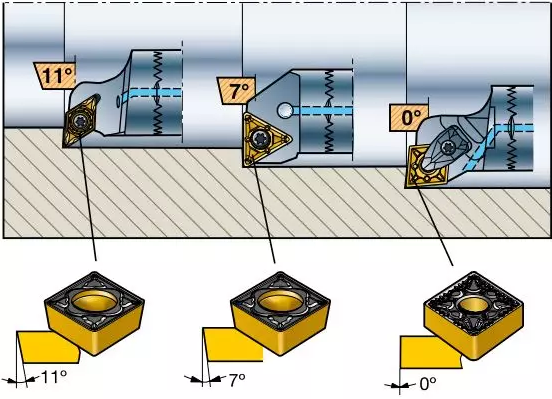

Two

Depending on the shape of the blade

The tool with positive rake angle has the characteristics of low cutting force and tool deflection

- Edge with Rear Angle 7°: preferred for small holes and medium holes over 6mm in diameter.

- Side with Rear Angle 11°: preferred when low cutting force and long overhang are required.

- To obtain the best economy, the negative rake angle blade used in stable working conditions and short overhang.

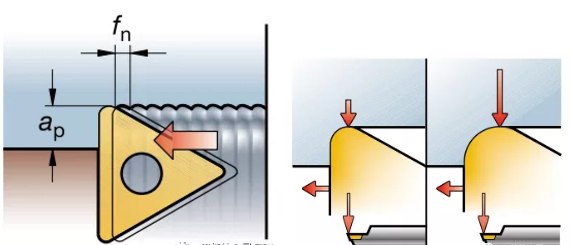

7.Relationship between chip area and tip radius

Cutting Force and tool deflection

- Small and large chip areas CAN CAUSE VIBRATION:

– high cutting force due to large chip area,

– small chip area causing friction between tool and workpiece.

- The relationship between the R tool tip radius and AP cutting depth affects the vibration trend.

- Smaller radial cutting force, minor deflection.

- Choose a tooltip radius that is slightly less than the thickness of the cut.

Leave A Comment