Introduction

Carbon content control is the core of quality control in the production of cemented carbide.

The relative magnetic saturation value mainly used to measure the carbon content in cemented carbide, and it needs to destroyed to measure the carbon content in cemented carbide by chemical method

The sample is a very complex process, the accuracy is limited, as a routine detection project, it is difficult to achieve.

The carbon content of cemented carbide can be calculated quickly, simply and accurately without destroying the alloy by using the high sensitivity of relative magnetic saturation to the carbon content of cemented carbide, and the repeatability is excellent.

With the development of science and technology, people require more and more precision to control the carbon content in cemented carbide

It is more and more critical to control the content of carbon in cemented carbide.

1.Magnetization curves of 1wc-co cemented carbide (M -H Curve)

Wc-co cemented carbide contains ferromagnetic cobalt. Therefore, it has ferromagnetic magnetic properties.

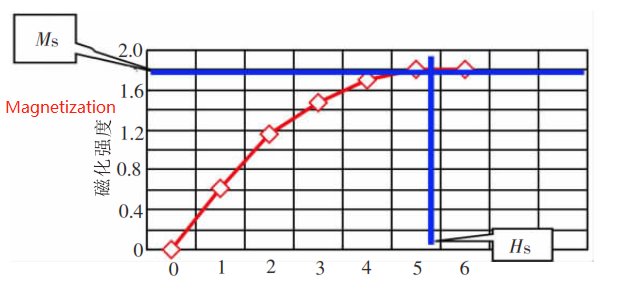

As shown in figure 1, when the magnetic field strength (H) increases gradually from zero.

The magnetization intensity (m) also increases gradually. When the magnetic field intensity (H) increases, and the magnetization intensity (m) no longer increases, the magnetization intensity (m) is called Saturation magnetization (Ms). The magnetic field intensity (h) is called saturation, and the magnetic field intensity (Hs).

Because the cobalt content in WC-Co cemented carbide is different, the carbon content is different

As opposed to. Different additive elements, different impurity elements, fig. 1 the magnetization curve of a particular tungsten-cobalt cemented carbide

It’s a specific kind of cemented carbide, each particular brand

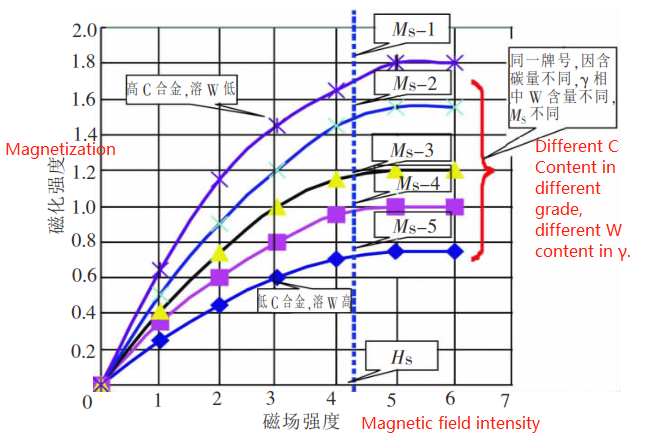

WC-CO cemented carbides have their own particular M-H magnetization curves. The saturation magnetization Ms of the alloy decreases with the increase of the solubility of W in y phase. For the same grade, we can draw M-H curves with different contents of W, as shown in Fig. 2, we can measure the MS values of various saturation magnetization of the same grade alloy with different w content.

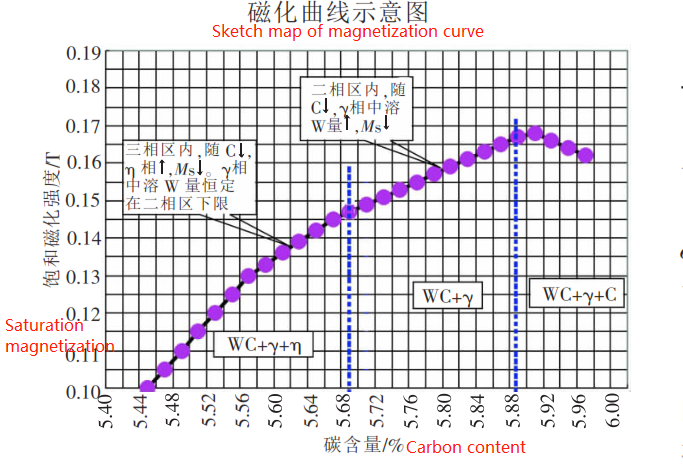

Because there is a good relationship between the amount of W in y phase and the amount of carbon in the alloy, we use the MS values of different saturation magnetization of the alloy with different w content of the same brand, the relationship between the run and magnetization of the grade and the carbon content of the alloy can be drawn as shown in Fig. 3.

In the two-phase region of WC + Y, the carbon content decreases with the increase of carbon content. The amount of W in the Y phase increases. Saturation magnetization decreases.

In the three-phase region of WC + Y +, the solid solubility of tungsten in the phase keeps constant at the lower limit of the two-phase area. With the decrease of carbon content, a part of the alloy becomes a non-magnetic phase, so the specific saturation magnetization of the alloy decreases with the reduction of carbon content.

Fig.2

Fig.3

2.Relative magnetic saturation of 2wc-co cemented carbide (relative saturation magnetization)

The ratio of saturation magnetization (4m8) of alloy y phase to that of pure cobalt (4m8) is called the relative saturation magnetization (relative magnetic saturation) of the Alloy y phase; the unit is%.

Composition: Alloy (Y phase) relative saturation magnetization (%) = (48, / 48 Cobalt 48 alloy / x) / (48 cobalt

At 20 °C, the specific saturation magnetization of pure cobalt is 48 cobalt 160 Gs · cm / g 2020 AM2 / kg.

Set: the specific saturation magnetization of the Alloy 4. 8 Alloy = E: CORRECTION FACTOR OF INSTRUMENT = 1. 0xx Each instrument Correction Coefficient is not the same, self-hardening instrument correction coefficient = 1.084 or 1.032. Before measuring the sample, measure the standard sample. Then calculate instrument Correction Coefficient).

Therefore, the relative magnetic saturation of the alloy (%) = EX1. 0XX / 1.6xW cobalt. The true cobalt content of the alloy.

According to the formula, the relative saturation magnetization of the alloy (phase y) can be calculated when the specific saturation magnetization of the alloy is measured from 4 to 5.

Conversely, according to the formula, we can calculate YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20, YG20

The relative magnetic saturation value of yg 6 alloy is 76%, 85%. 92%, 94%,

the benefits of 96%, and 100% specific saturation magnetization e are shown in Table 1. Root

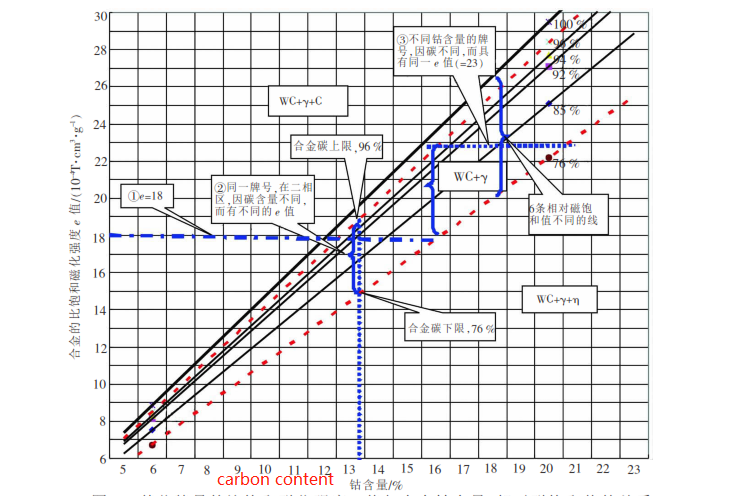

Figure 4, according to Table 1.

Table 1yg6 and YG20 alloys with different relative magnetic saturation values

Thee value of specific saturation magnetization

Fig. 4 shows the relationship between the specific saturation magnetization e value of the alloy and the cobalt content and the relative saturation value of the alloy

Table 1.

(1) when the value of e (such as YGI3C, cobalt 13%, e 18) of a brand is measured, we can see from the diagram that the relative magnetic saturation value of the brand is about 92%, which is located at the upper limit of the two-phase zone, that is, the alloy carbon content is located at the upper limit of the two-phase zone

(2) the upper limit of relative magnetic saturation is 96%, and the lower limit is 76%. Each brand (cobalt content fixed, such as W. The relative magnetic saturation value of 13% has a fluctuation range due to carbon difference (i. e. the upper limit and the lower limit of the corresponding magnetic saturation line are crossed by the cobalt-bearing point as a vertical line, that is, the upper limit and the lower limit of the allowable carbon content fluctuation in the two-phase region are higher than, the upper limit, the free carbon in the alloy is lower than the lower limit, and the phrase appears in the alloy)

The range of motion increases (YG16 > Yg13.

(3 different grades with different cobalt content may be possible due to altered carbon content

Have the same e value. For example, e = 23, which is the opposite of YG16

The upper limit of the magnetic saturation phase zone is YG21 alloy

The lower limit of the phase region.

There is also a description of relative magnetic saturation: The ratio of the cobalt magnetic (Com) of the alloy to the cobalt content (W cobalt) of the alloy measured (Com / W cobalt).

Known as the alloy’s relative magnetic saturation value. That is:

Alloy (Y phase) is relatively magnetically saturated BIS (48, / 48 cobalt com / W cobalt

To study the magnetism of alloy is to study the magnetism of y phase in alloy. As mentioned above, the reduction of carbon in WC-Co cemented carbide leads to an increase of w content in y phase, which leads to a decrease of magnetic properties of y phase, when we measure the specific saturation magnetization of different grades of alloys with different carbon content and strength of 48 alloys, we can calculate different relative magnetic saturation values of different grades of alloys with different carbon content and plot them in figure 5.

Fig. 4 shows the relationship between the specific saturation magnetization e value of the alloy and the cobalt content and the relative magnetic saturation value of the alloy:

Fig.4

Fig.5

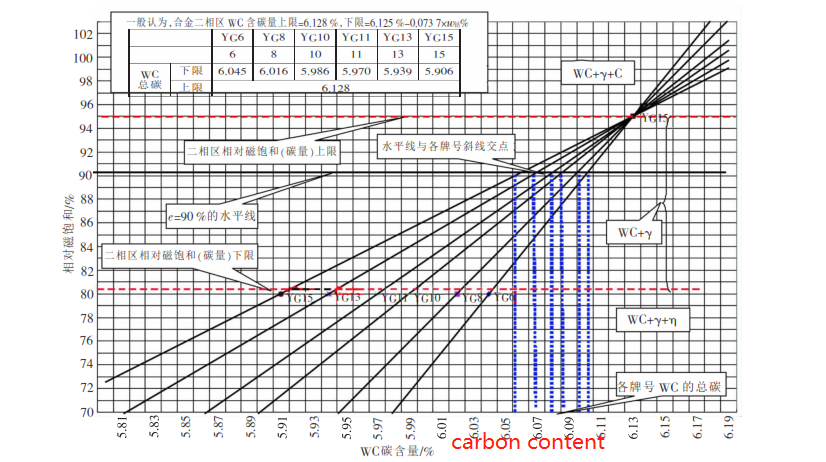

The lines in figure 5 show:

(1) each diagonal line in the diagram represents a brand with a different cobalt content.

(2) the Abscissa in the chart is the total carbon of the alloy WC.

(3) the vertical coordinates in the chart are the relative magnetic saturation values of the alloy.

(4) the two dashed lines in the drawing are the boundary lines of the alloy phase zone.

The upper limit of the two-dashed line is 75% (or 80%), and the relative magnetic saturation value of the alloy is about 75% (or 80%). That is to say, the alloy’s relative magnetic saturation value is higher than the upper limit, carburizing occurs in the alloy, the alloy

The relative magnetic saturation value is less than the lower threshold, and decarburized phase-phase appears in the composite.

(5) the total carbon of WC of the alloy is equal to the total carbon of the alloy, as shown in figure 5. The total carbon of alloy YG6, YG8, YG10, YG11, YG13, and YG15 is equal to about 6 when the relative magnetic saturation is equal to 90%. 10% 6. 09% 6. 08% , 6. 07% , 6. 06% 6. 05% . That is when we measure the relative magnetic saturation value of the alloy, the magnetic saturation value of the alloy

In this figure, we can find the total carbon of WC of this alloy.

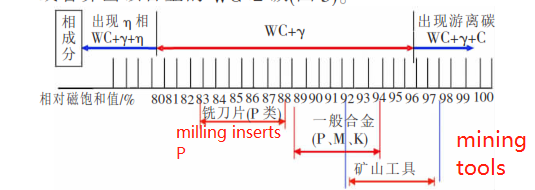

Due to the different use of cemented carbide, it is required that cemented carbide have different properties and structure, and also different carbon content. We can choose the relative magnetic saturation value of the alloy when the effect of the alloy is the best by experiment

The standard for relative magnetic saturation values of grades. We can then relate the range of use, phase composition, and corresponding magnetic saturation criteria of the cemented carbides, as shown in figure 6. That is to say; different cemented carbides require different amounts of carbon or relative magnetism

Mixed saturation, changed position in the two-phase region.

When the relative magnetic saturation of the alloy has been determined, we can determine whether the alloy is suitable for various uses (Fig. 6) or calculate the total WC carbon of the alloy (Fig. 5).

Fig. 6 use range, phase composition and relative magnetic saturation of cemented carbide And standards.

Fig.6

3.Relationship Between magnetic saturation and properties of cemented carbide

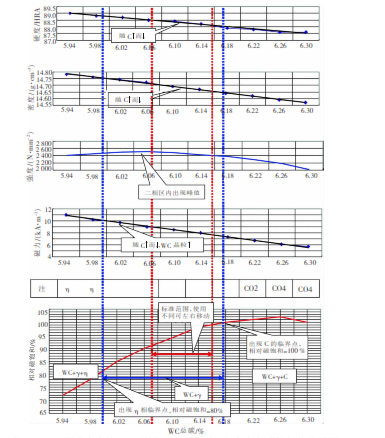

Among the properties of cemented carbide, some features are dominant, which influence and determine other properties. For a specific brand, the cobalt content and WC grain size are fixed, at which point the total carbon of the WC (assuming that the alloy has no structural defects) has a decisive effect on other properties of the composite, that is to say, the relative magnetic saturation value of the alloy is the dominant property of the alloy.

When the relative magnetic saturation value is determined, there is a strict relationship between it and other features, other performance can only fluctuate within a specific range, as shown in figure 7.

For example, the best comprehensive service performance of cemented carbide for mine appears in; the relative magnetic saturation is 92% ~ 96%, that is, the best-cemented carbide for mine

The composite performance appears in the upper limit edge zone of WC + Y phase zone, that is, the alloy will have free carbon but no free carbon, the relative magnetic saturation value (96%) of the alloy is defined as the upper limit of the standard of the relative magnetic saturation value of the alloy, and the lower limit of the rule should be determined according to the control level.

Fig. 7 illustrates the process of drawing up the relative magnetic saturation standard of YG8 alloy: the mixture is made by using WC with different total carbon, the sample is made by pressing and sintering, the properties of the sample are tested, and the results are drawn into Fig. 7. As can be seen from Fig. 7, the relative magnetic saturation of the alloy increases gradually with the increase of total WC carbon and decreases slightly after the maximum value.

It can be said that for a particular grade (cobalt content, WC particle size, and processing parameters are fixed), the relative magnetic saturation dominant property when the relative magnetic saturation value of cemented carbide is determined due to the different use of cemented carbide, other features are also identified. There is a strict relationship between them, and their properties can only fluctuate in a particular range,

4.The accuracy of measuring carbon content in cemented carbide with relative magnetic saturation

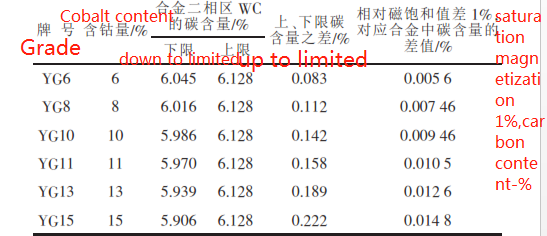

Because the relative magnetic saturation value of cemented carbide is highly sensitive to the carbon content in cemented carbide, the carbon content in cemented carbide can be measured accurately by using the relative magnetic saturation energy. As shown in table 2,1% of the relative magnetic saturation of YG6 alloy corresponds to 0.0056% of the difference in the carbon content of the alloy, and 1% of the relative magnetic saturation of YG15 alloy corresponds to 0.0148% of the difference in the carbon content of the alloy, that is to say, the resolution of carbon content in YG6 alloy and YG15 alloy can reach 0.56 and 1.48,

Table.2

Table 2 accuracy of carbon content in cemented carbide with relative magnetic saturation

According to figure 5, the difference between the relative magnetic saturation (upper-lower limit) and the corresponding carbon content (upper-lower limit) in the two-phase region is 16% and 0.11%, that is, if the relative magnetic saturation of the alloy can be measured with 1% accuracy, the resolution of carbon content in Yg 8 fusion is 0.69.

The phase composition of the alloy (WC + . WC + + C.WC + +) can also be determined by the relative magnetic saturation. It can judge the position (upper, middle, and lower limits) of the alloy in the two-phase zone of WC +, and can effectively evaluate the serviceability of the composite to Mo seeds (figure 6).

Other mechanical properties of the alloy can also be indirectly evaluated according to its magnetic saturation value (Fig. 7).

Fig.7

5.Have you ever had a supplier test you and come up with a conclusion, a numerical result.

You do not know some factory inside the test equipment, just for show to the customer.

These testing equipment are highly environmentally demanding, in addition to having professional technical personnel,

require constant temperature and humidity, and to some from the road, why should be far from the road

Fear of creating harmonic resonance, which could compromise the accuracy of the test.

Calibration test equipment parameters, how to proofread, proofreading based on what?

Leave A Comment