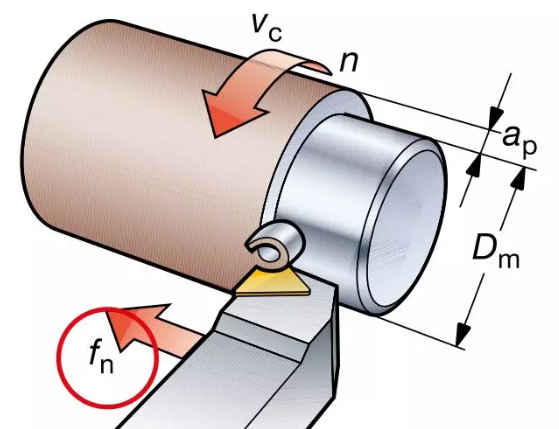

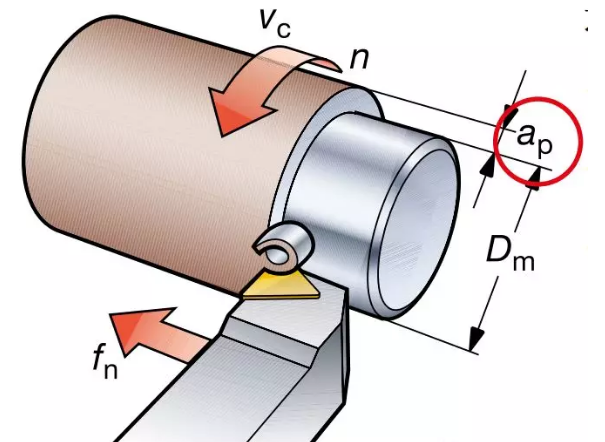

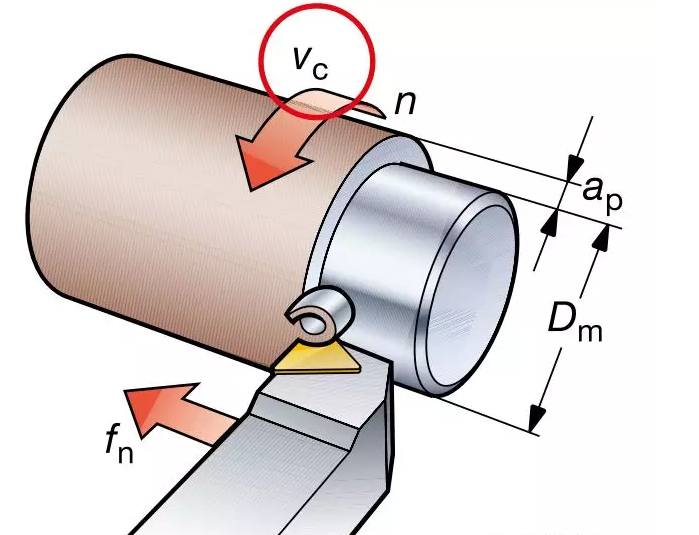

Cutting speed VC

The cutting speed (VC) is the instantaneous velocity of a point on the cutting edge in the main direction of motion relative to the surface to be machined.

Notes:

VC: Cutting Speed (m / min)

N: spindle speed (rev / Min)

D: workpiece diameter (mm)

FORMULA:

VC=πXDxn/1000(m/min)

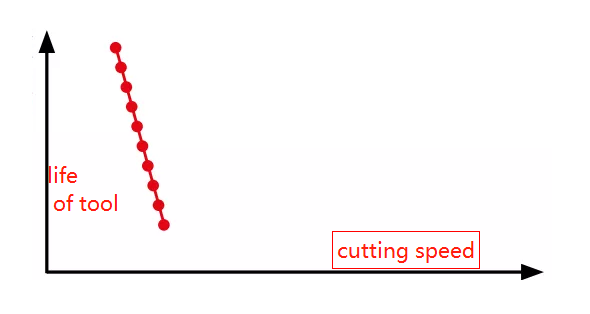

Influence of cutting speed on tool life

The single most significant factor determining tool life

Excessive cutting speed:

- rapid flank wear

- Poor surface quality

- Rapid Crescent depression wear

- plastic deformation

LOW CUTTING SPEED:

- SCURF tumor

- Poor economy.

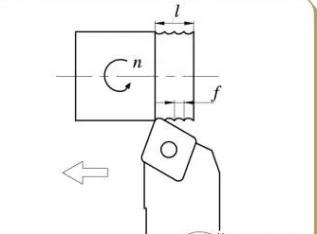

Feed F

Feed Rate F is the displacement of the tool relative to the workpiece in the direction of feed motion.

Notes:

F: Feed per revolution (mm / Rev)

L: cutting length per minute (mm)

N: spindle speed (REV / Min)

FORMULA:

F=l/n(mm/rev)

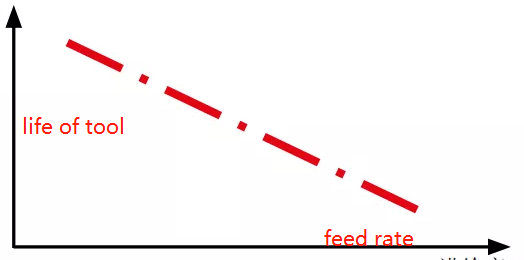

Influence of feed rate on machining

The single most significant determinant of productivity

Excessive feed rate:

- No chip control

- Poor surface quality

- Crescent depression wear and plastic deformation

- High Power consumption

- Chip Fusion

- Chip impact.

LOW FEED RATE:

- long chips

- Poor economy.

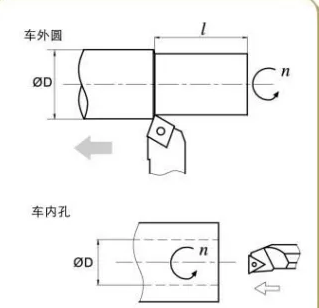

Calculation of cutting time of outer circle and inner hole

Notes:

T: Cutting Time (Min)

L: Length of the part to cut (mm)

N: spindle speed (REV / Min)

Calculation formula;

T=l/f*n(min)

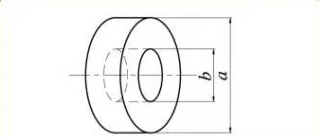

Calculation of end face cutting time (constant linear speed)

Notes:

T: Cutting Time (Min)

VC: Cutting Speed (M / min)

F: Feed (mm / REV)

When there is no internal hole in the cut end face, B0

FORMULA:

T=π*(a2-b2)/4000XVcXf(min)

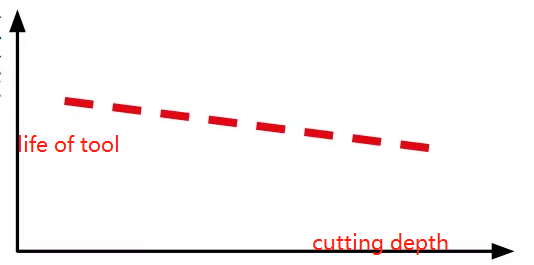

Influence of cutting depth

Cutting too deep:

- High Power consumption

- Blade Rupture

- higher cutting force

TOO SMALL DEPTH OF CUT:

- No chip control

- vibration

- overheating

- Poor economy.

Leave A Comment