Project Description

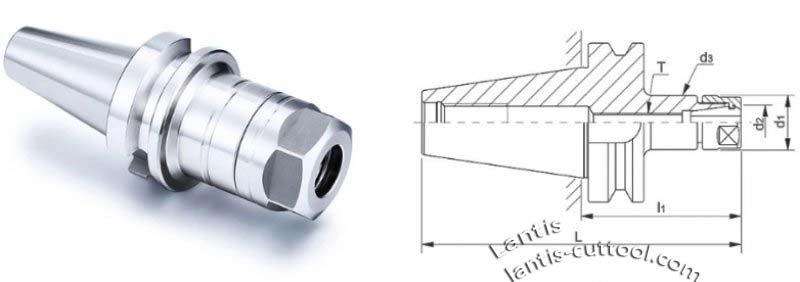

CNC Face Mill Tool Holder

Product Description

- Screw thread in the Front of Shank .

- Accuracy of Thread is ±0.005mm.

- Netted design at the end of shank:

- better balance, higher balancing factor, suitable for high-speed process.

- Cryogenic Treatment : Increase the surface hardness, HRC50-53 degree.

- Combination of precision : Pull stud + tool holder + collets + end mills = 0.01

PRODUCT PARAMETER

- Name: CNC face mill tool holder

- Overall clamping jump ≤o.008

- Materials: steel materal 20CrMnti

- Roundness: <0. 8u

- Specifcation: Body accuracy

- Deep carburizing degrees: >0.8mm

- Body accracy:≤0.0o8mm

- Hardness;≤HRC50°

| Item No. | Size | |||||

|---|---|---|---|---|---|---|

| L1 | L | d1 | d2 | d3 | ||

| BT-30 | ER11-70 | 70 | 118.4 | 99 | 11 | 19 |

| ER11-100 | 100 | 148.4 | 19 | 11 | 19 | |

| ER16-70 | 70 | 118.4 | 28 | 16 | 28 | |

| ER16-100 | 100 | 148.4 | ||||

| ER20-70 | 70 | 118.4 | 34 | 20 | 34 | |

| ER20-100 | 100 | 148.4 | ||||

| ER25-70 | 70 | 118.4 | 42 | 25 | 42 | |

| ER25-135 | 135 | 148.4 | ||||

| ER32-70 | 70 | 118.4 | 50 | 32 | 50 | |

| ER32-100 | 100 | 148.4 | ||||

| ER40-80 | 80 | 128.4 | 63 | 40 | 63 | |

| BT-40 | ER11-70 | 70 | 118.4 | 19 | 11 | 19 |

| ER11-100 | 100 | 148.4 | 19 | 11 | 19 | |

| ER16-70 | 70 | 135.4 | 28 | 16 | 28 | |

| ER16-100 | 100 | 165.4 | ||||

| ER16-150 | 150 | 215.4 | ||||

| ER20-70 | 70 | 135.4 | 34 | 20 | 34 | |

| ER20-100 | 100 | 170.4 | ||||

| ER20-150 | 150 | 215.4 | ||||

| ER25-70 | 70 | 135.4 | 42 | 25 | 42 | |

| ER25-100 | 100 | 165.4 | ||||

| ER25-150 | 150 | 215.4 | ||||

| ER32- 70 | 70 | 135.4 | 50 | 32 | 50 | |

| ER32-100 | 100 | 165.4 | ||||

| ER32-150 | 150 | 215.4 | ||||

| ER40-80 | 80 | 135.4 | 63 | 40 | 63 | |

| ER40-100 | 100 | 145.4 | ||||

| ER40-150 | 150 | 215.4 | ||||

| BT-50 | ER16-100 | 100 | 201.8 | 28 | 16 | 28 |

| ER16-150 | 150 | 251.8 | ||||

| ER16-200 | 200 | 301.8 | ||||

| ER20-100 | 100 | 201.8 | 63 | 40 | 63 | |

| ER20-150 | 150 | 251.8 | ||||

| ER20-200 | 200 | 301.8 | ||||

| ER25-100 | 100 | 201.8 | 42 | 25 | 42 | |

| ER25-150 | 150 | 261.8 | ||||

| ER25-200 | 200 | 301.8 | ||||

| ER32-100 | 100 | 201.8 | 50 | 32 | 50 | |

| ER32-150 | 150 | 251.8 | ||||

| ER32-200 | 200 | 301.8 | ||||

| ER32-250 | 250 | 351.8 | ||||

| ER40-100 | 100 | 201.8 | 63 | 40 | 63 | |

| ER40-150 | 150 | 251.8 | ||||

| ER40-200 | 200 | 301.8 | 78 | 50 | 78 | |

| ER40-250 | 250 | 351.8 | ||||

| ER40-300 | 300 | 401.8 | ||||

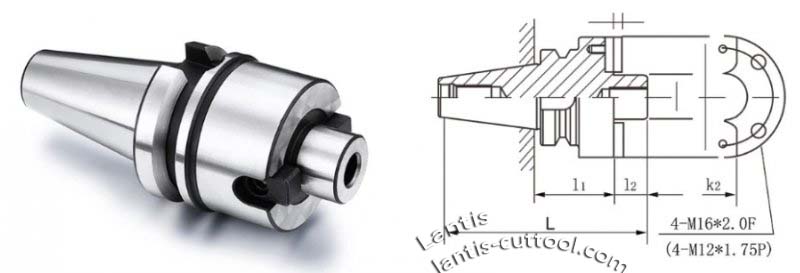

Drill Chuck Abors In Tool Holder

| Item No. | SIZE | Weight KG | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| d1 | L1 | D | d2 | L | l2 | K1 | K2 | |||

| BT-30 | FMB22-45 | 22 | 45 | 48 | 26 | 114.4 | 18 | 4.8 | 10 | 0.85 |

| FMB22-60 | 60 | 126.4 | 1.25 | |||||||

| FMB27-45 | 27 | 45 | 60 | 31.5 | 113.4 | 20 | 5.8 | 12 | 1.2 | |

| FMB27-60 | 60 | 128.4 | 1.35 | |||||||

| FMB32-45 | 32 | 45 | 78 | 41 | 115.4 | 22 | 6.8 | 14 | 1.35 | |

| BT-40 | FMB22-60 | 22 | 60 | 48 | 26 | 143.4 | 18 | 4.8 | 10 | 1.7 |

| FMB22-100 | 100 | 183.4 | 2.2 | |||||||

| FMB22-150 | 150 | 233.4 | 3.1 | |||||||

| FMB22-200 | 200 | 283.4 | 3.1 | |||||||

| FMB27-60 | 27 | 60 | 60 | 31.5 | 145.4 | 20 | 5.8 | 12 | 2 | |

| FMB27-90 | 90 | 175.4 | 2.3 | |||||||

| FMB27-105 | 105 | 190.4 | 2.5 | |||||||

| FMB32-60 | 32 | 60 | 78 | 41 | 147.4 | 22 | 6.8 | 14 | 2.1 | |

| FMB40-60 | 40 | 60 | 80 | 48 | 150.4 | 25 | 8.3 | 16 | 2.8 | |

| BT-50 | FMB22-90 | 22 | 90 | 48 | 26 | 209.8 | 18 | 4.8 | 10 | 5.1 |

| FMB22-150 | 150 | 269.8 | 6.8 | |||||||

| FMB22-200 | 200 | 319.8 | 7 | |||||||

| FMB22-250 | 250 | 369.8 | 8 | |||||||

| FMR22-300 | 300 | 60 | 400 | / | ||||||

| FM822-350 | 350 | 450 | 10.5 | |||||||

| FM822-400 | 400 | 500 | / | |||||||

| FMR27-90 | 27 | 90 | 31.5 | 211.8 | 20 | 5.8 | 12 | 5.4 | ||

| FMB27-150 | 150 | 271.8 | 7.5 | |||||||

| FM827-200 | 200 | 321.8 | 9.5 | |||||||

| FMB27-250 | 250 | 371.8 | 11 | |||||||

| FMB32-90 | 32 | 90 | 78 | 41 | 213.8 | 22 | 6.8 | 14 | 5.8 | |

| FMB40-90 | 40 | 90 | 89 | 48 | 216.8 | 25 | 8.3 | 16 | 6 | |

| FMB40-105 | 105 | 98 | 231.8 | 7.2 | ||||||

| FMB40F-75 | 75 | 110 | / | 202.8 | 26 | 6 | ||||

| FM60-75 | 60 | 75 | 128.57 | / | 201.8 | 25 | 12.5 | 25.4 | 8.5 | |