Project Description

Features of inserts for stainless steel

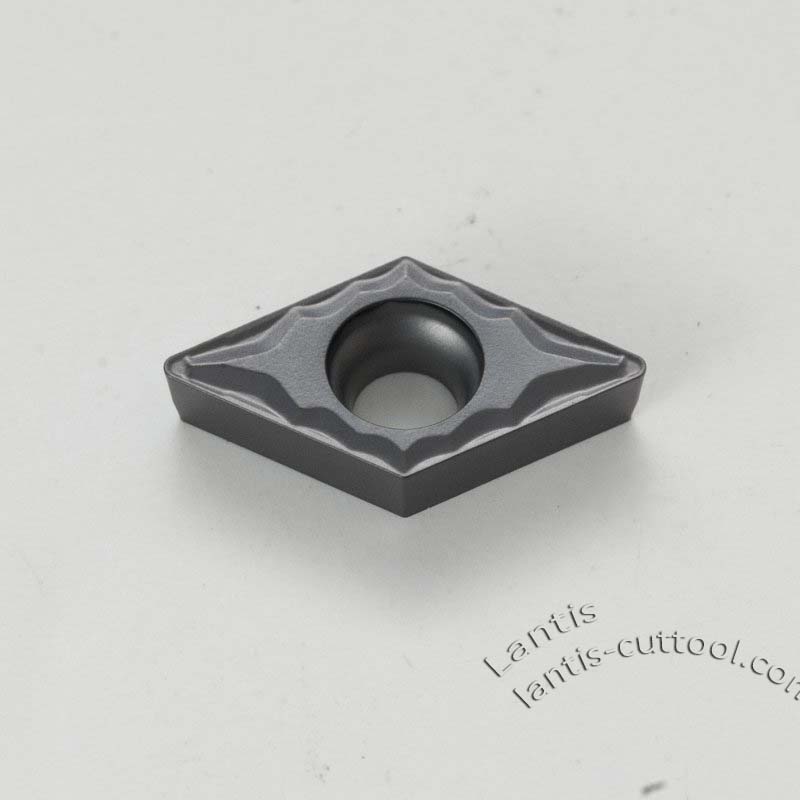

- The unique design chip breaker has excellent performance of stainless steel for rough machining, semi-finishing machining, and finishing machining

- BF-chip breaker inserts are used for semi-finishing machining and finishing a suitable surface. The specific

chip breaker solved the burr phenomenon on the surface of the part. - BM-Chipbreaker inserts are the first choice for stainless stell typical machining, the cutting tools with both sharpness and hardness, which proper use to semi-finishing and rough turning.

- Well-solved, the difficulty of the stainless steel hard chip breaking, sticking, surface hardening, etc., thus obtain the high-quality surface.

- Individual chip breakers can control the chipping direction, thus raises the production efficiency and reduce the built-up edge occur.

- There are different designs for rough machining,semi-finishing machining, and finishing machining. The inserts for fishing and semi-fishing have emphasized the sharpness of cutting edge. To optimize the cutting edge for rough machining inserts, well balanced the safety and sharpness, improved service efficiency of the tool.

Features of inserts for stainless steel

- The unique design chip breaker has excellent performance of stainless steel for rough machining, semi-finishing machining, and finishing machining

- BF-chip breaker inserts are used for semi-finishing machining and finishing a suitable surface. The specific

chip breaker solved the burr phenomenon on the surface of the part. - BM-Chipbreaker inserts are the first choice for stainless stell typical machining, the cutting tools with both sharpness and hardness, which proper use to semi-finishing and rough turning.

- Well-solved, the difficulty of the stainless steel hard chip breaking, sticking, surface hardening, etc., thus obtain the high-quality surface.

- Individual chip breakers can control the chipping direction, thus raises the production efficiency and reduce the built-up edge occur.

- There are different designs for rough machining,semi-finishing machining, and finishing machining. The inserts for fishing and semi-fishing have emphasized the sharpness of cutting edge. To optimize the cutting edge for rough machining inserts, well balanced the safety and sharpness, improved service efficiency of the tool.

Features of inserts for steel

- GM-chip breaker inserts have a sharp cutting edge, achieving easy and fast cutting in semi-finishing machining. It optimized the small cutting deep machining machinability, especially have excellent performance when processing the workpiece material like soft steel, etc.

- GR-chip breaker optimized the structure of cutting edge and improved the edge strength, more safety, and reliability in intermittent rough turning.

- A specific chip breaker can effectively control chipping flow direction, which achieves easy and fast cutting and improve the inserts’ service life.

- Small cutting force reduces the cutting vibration and obtains high quality finished workpiece surface.

- The combination of optimized substrate and coating increases the binding force, reducing the accidental processing failure caused by layer disbanding in cutting machining.