Choose a general-purpose guide.

- The reliable clamping of the blade and the tool holder is the basic premise to keep the stability in turning.

- The handle type is determined by the primary offset angle, shape, and size of the blade used.

- The selection of the tool holder system is mainly based on the type of working procedure.

- Another important choice is whether to use a negative or positive rake blade.

- Choose modular tools whenever possible.

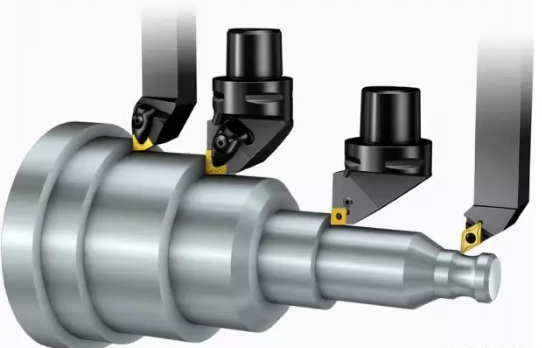

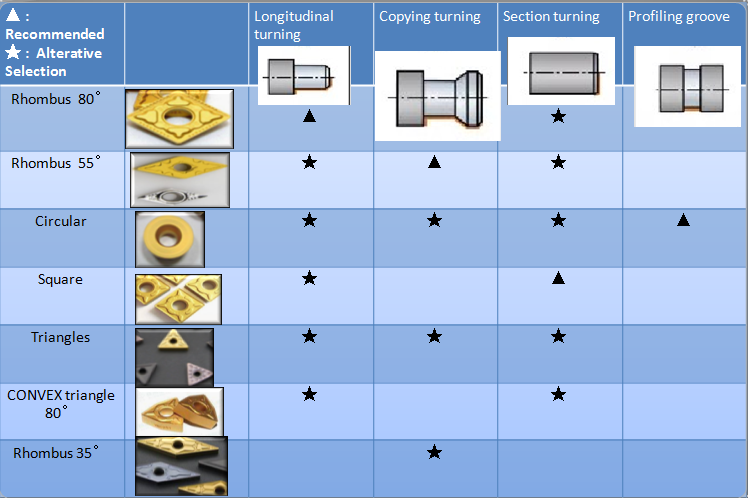

Guide for selection of cylindrical turning inserts

Four main areas of application

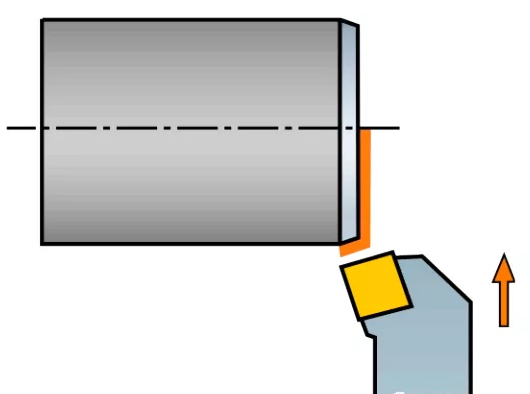

One

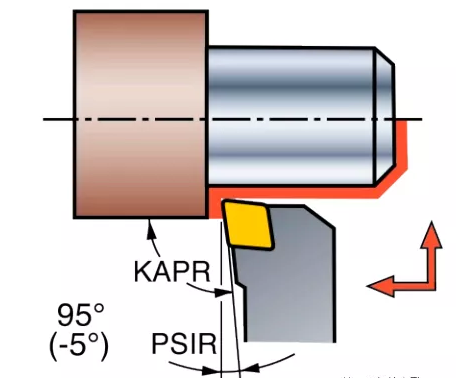

Longitudinal turning/end turning

The most common turning process

- A diamond-shaped c-80° blade commonly used.

- Hilts with the main declination angles 95° and 93°, and Angle of entry-5° and-3° widely used.

- The replacement options for type C are type D 55°, type W 80°, and type T 60°.

Two

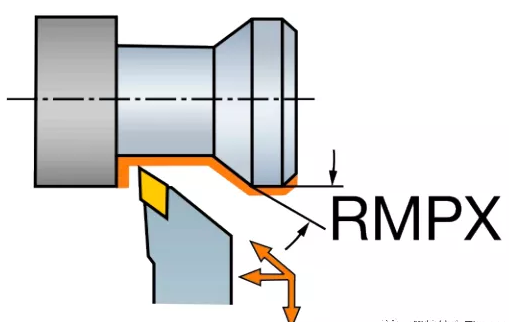

Copying cutting

Generality and accessibility are the determining factors

- To obtain satisfactory machining results, the effective central deflection angle Kapr cut-in Angle Psir should be considered.

- The most commonly used central deflection angle is 93°, and the Angle of entry is-3° because it allows for an internal profiling angle of 22°-27°.

- The most widely used blade shapes are d-55° and v-35°.

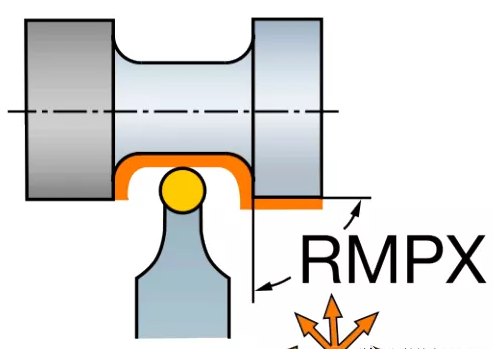

Three

End Turning

The cutter feeds along the Radial Direction

- Note the cutting speed, which will change gradually as the feed goes along the radial direction.

- The standard principal declination angles are 75° and 95° / 91°, and the Angle of entry is 15° and-5° /-1°.

- c-80° and s-90° blades commonly used.

Four

Profile cutting

A method of machining or widening a shallow groove

- The circular blade is ideal for inserting vehicles because it can use for both radial and axial feed.

- A round edge with 90° handles commonly used.

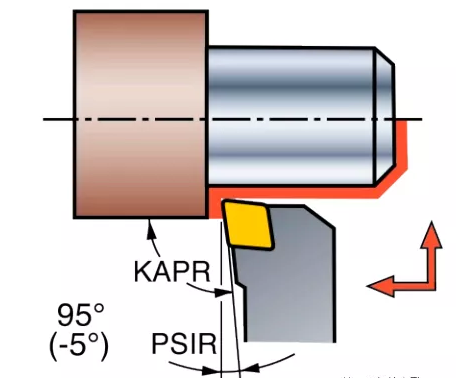

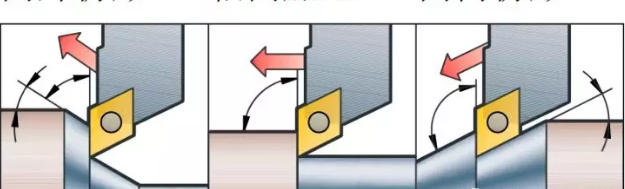

Benefits of large and small principal declinations

One

Benefits of a large deflection angle

The Angle of large principal deflection and small Angle of entry

- The cutting force directed to the chuck

- capable of shoulder turning

- higher cutting force when cutting in and out of the workpiece

- Wear and tear of grooves is prone to occur in the processing of superalloys and hard materials

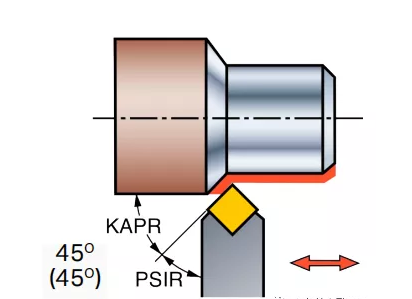

Two

Benefits of small principal declination

Small Main Deflection, large Angle of entry

- The chips produced are thinner

- productivity growth

- groove wear reduced

- the shoulder can not turn

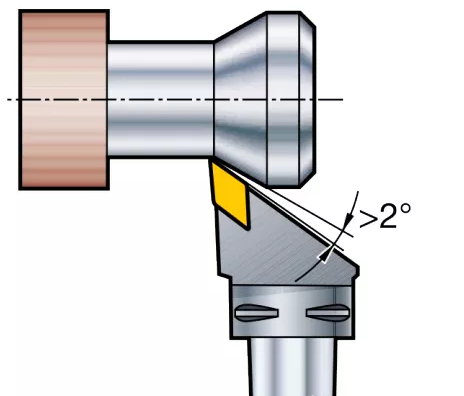

Central deflection angle and profile angle

- In profiling turning, the cutting conditions vary with the depth, chip thickness, degree, and cutting speed.

- Choose the maximum blade angle suitable for the blade to ensure strength and cost-efficiency. Still, the blade accessibility must also be considered when considering the blade angle to ensure proper clearance between the material and the cutting edge.

- The most commonly used knife points are 55° and 35°.

- Both the central deflection /Angle of cut and the Angle of tooltip are essential factors affecting accessibility. Choose the most suitable profile angle; the profile of the workpiece must be analyzed.

- A minimum of 2° corners of avoidance must be maintained between the workpiece and the blade.

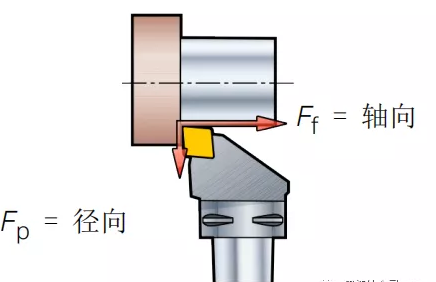

Axial and radial cutting forces

One

Large central deflection angle (small Angle of entry)

- The cutting force directed to the chuck. Vibration trend reduction.

- Higher cutting forces, especially when cutting in and out of the workpiece.

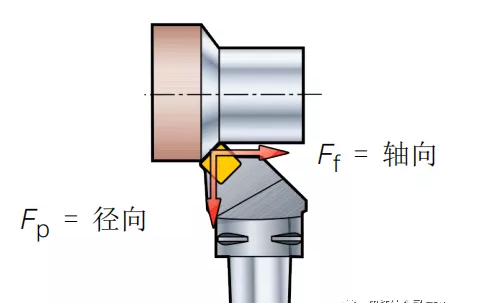

Two

Small Main Deflection Angle (large Angle of cut)

- The cutting force distributed along with both axial and radial directions.

- Reduced load on the cutting edge.

- The cutting power distributed along with both axial and radial directions.

- Vibration trend.

Leave A Comment